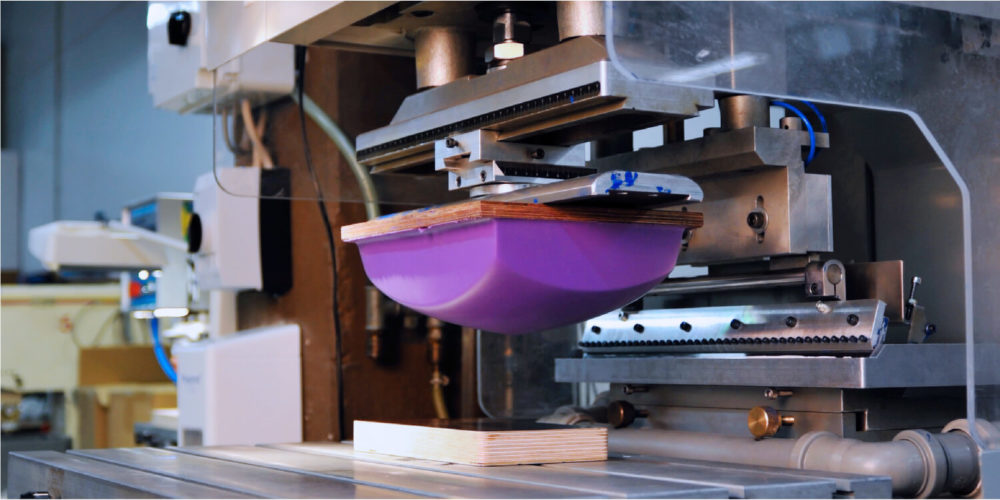

Printing and finishing processes Pad printing for 360° creativity

As an indirect gravure printing process, pad printing has special unique selling points among the finishing processes. Due to the elasticity of the pad, concave and convex shapes can be printed. In addition to the possibility of refining the most varied printing materials, this printing process is characterised by rich colours which produce an excellent print image. Depending on the printing machine, articles can be printed up to 360°.

Before an advertising novelty is printed on with the help of the pad – which by the way can be imagined like a stamp – the print motive is first etched on a so-called cliché. Thereby it is possible to realize very fine and gracile motifs on a very small area. The etched areas are then filled with ink, which in turn is absorbed by the pad and applied to the desired printing area.

How does the pad printing process work?

The transfer of the motif onto the printing material is extremely precise, as the pad can adapt to the shape of the printing body due to its elasticity.

Thus, pad printing is very popular in the promotional products sector, as all articles can be refined using this process. Among others, classics such as ballpoint pens, drinking bottles, lighters or power banks – an impressive printing process all round that guarantees 360° creativity .

Source image: © jas – stock.adobe.com

Source image: © jas – stock.adobe.com