Printing and finishing processes Individual personalisation thanks to digital printing

Strictly speaking, digital printing or non impact printing is simply the name of a group of different printing processes that all have one thing in common: They function without the use of a physically solid printing body. This makes the costly production of a printing form unnecessary. The desired print file is sent to the printing machine by computer and immediately transferred to the respective substrate by means of laser, thermal, photo or inkjet printing.

What are the advantages of the digital printing process?

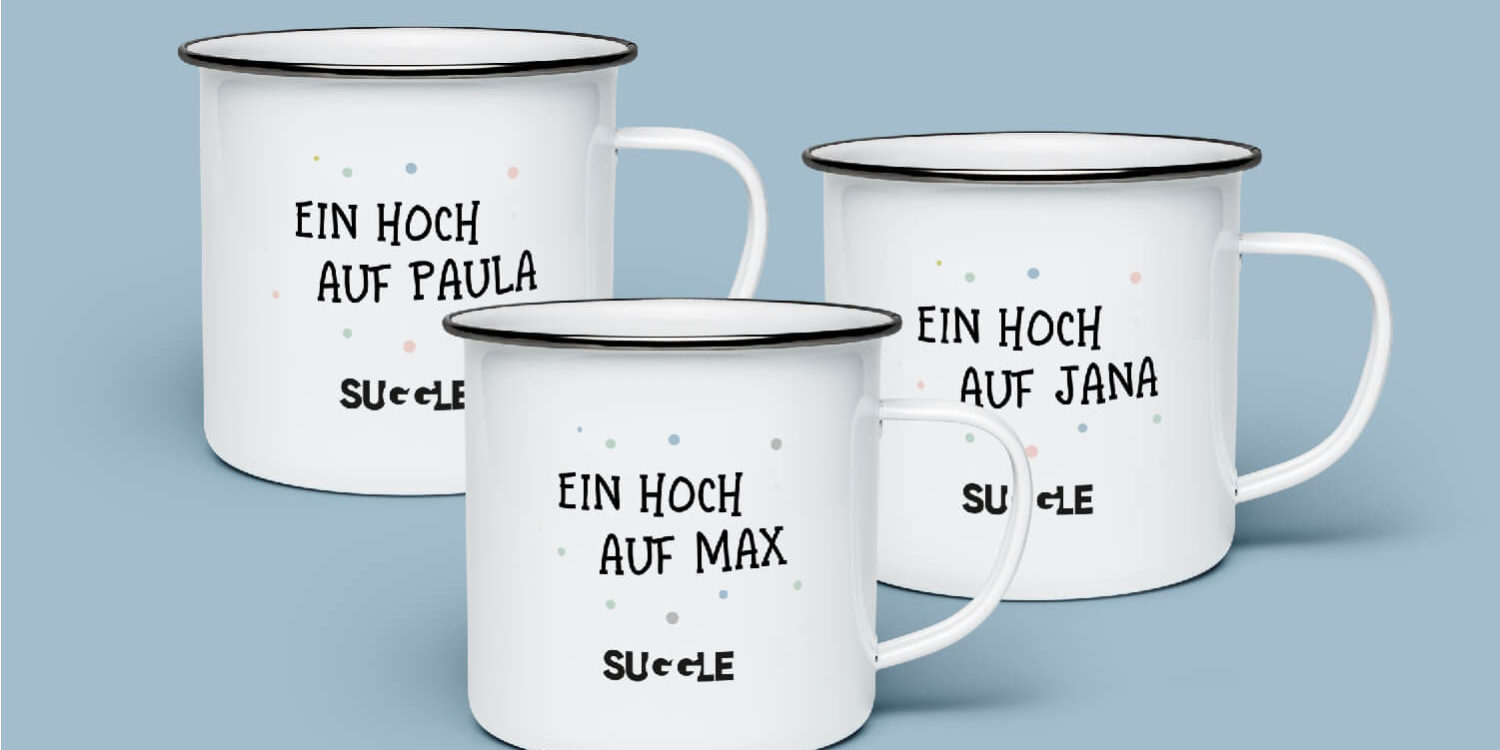

Digital printing plays an extremely important role in the field of advertising material finishing, not only because of the minimal preparation work. Thanks to the high degree of flexibility in personalization it creates unique possibilities for the individual design of give-aways. Each individual copy can be given its own print image if required. This means that both short and long runs of personalized substrates can be produced cost-effectively.

In addition to its uncomplicated application, digital printing is particularly characterised by its high printing speed, which goes hand in hand with very good quality. Flexible as well as rigid or curved surfaces of any material can be printed. Thus digital printing is used for the design of all kinds of promotional items, including cups, glasses, coffee cups, clothing, toys, ballpoint pens, lanyards, packaging and so on and so forth…